We have accumulated a lot of experience on the subject, which has enabled us to find a solution with two drawers: the first social, the second environmental.

In any case, the starting point is you! We ask you to bring your used Benjies back to the store so that we can sort them.

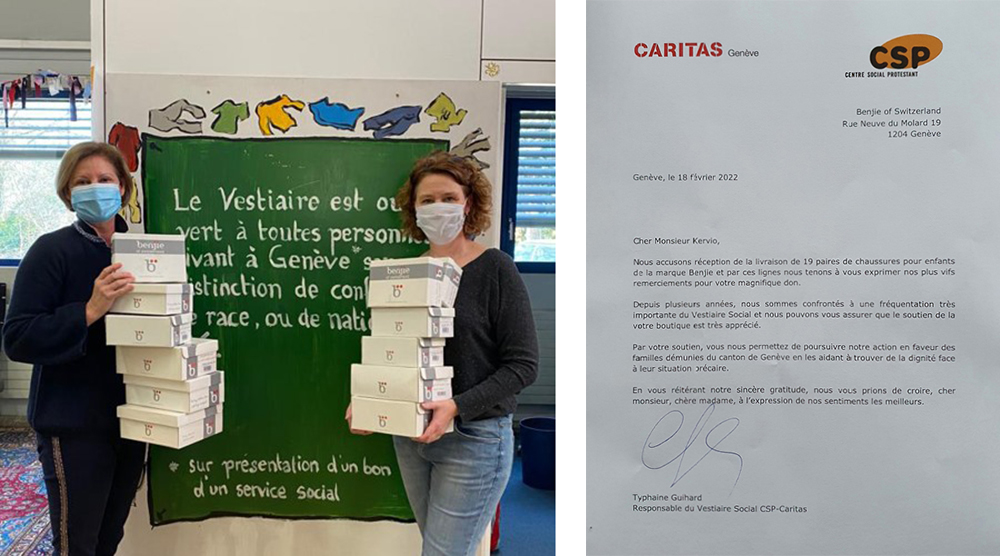

Those that are in good condition are given to the Vestiaire Social du CSP / Caritas in Geneva. The ones that are very damaged are used as raw material for the manufacture of new Benjie soles.

FIRST, A POINT ON SHOE RECYCLING: THE MYTH... AND THE REALITY

Let's start with the ideal: the circular economy. The principle is simple, let's take the example of a wool sweater (single material). We take once the wool from the sheep. The sweater is produced, sold and used by the consumer. At the end of its life, worn out, the consumer separates it to recycle it. The new wool, resulting from this recycling, is used to make a new sweater.

Thus the worn sweater was used to manufacture the new sweater without any new resource being used.

Unfortunately, it is almost impossible to recycle a pair of shoes to make exactly the same new pair. We say "almost impossible" because technology is advancing rapidly and we do not pretend to know everything.

This is due to one main reason: a shoe is made of 5 to 15 different materials. In fact, the shoes you are reading this article are probably made of textile, leather, cardboard, rubber, metal, paper, TR, cotton, nylon, wool, polymers of many kinds and the list goes on.

The materials that make up a pair of Benjie

There are two ways around this problem.

- The first solution would be to revolutionize the design of the shoe by making it a mono or bi-material product, therefore possibly 100% recyclable. But, realistically, there are many obstacles. A shoe made entirely of leather or fiber, for example, would not withstand the intensive use of a child (abrasion of the sole, rubbing on the upper, etc.). A shoe made entirely of plastic would not be breathable, nor comfortable enough for the child, not to mention that this material is made from fossil fuels, and therefore polluting.

- The second solution would be to get around the problem of multi-materiality by having an industrial process that allows the materials that make up the shoe to be separated when it reaches the end of its life. Each material would then be recycled separately and used to remanufacture the same shoe later. There are several serious avenues that we have already studied, including that of a lab at the EPFL. However, the tests are extremely expensive for a small structure like Benjie. Moreover, the process is still at the study stage and not at an industrial application level.

It is the only truly worthwhile challenge in terms of long-term sustainability. We were inspired to do this when we read former sailor Ellen MacArthur's wonderful book Les pieds sur terre -2010- Editions Glénat. She explains how her ecological vocation was born. The understanding of the principles of the circular economy that allowed her to move from an ecology of restriction to an ecology of development. The basis of "consuming differently and sustainably". A great source of hope and meaning.

This is why we wanted to imagine a new way: realistic and actionable NOW!

From navigator to promoter of the circular economy. A great source of inspiration.

Storage facilities for sorted clothes in the canton of Uri

WHAT HAVE WE DONE SO FAR AND WHY DO WE WANT TO CHANGE?

We started with a partnership with Emmaus and TEXAID. We collected shoes at the end of their life (Benjie and other brands) to give them to TEXAID who sold them in part to the main Swiss charities. Those that were too damaged were destroyed.

In the end, we were no more and no less than a collection box, like those found everywhere in Switzerland.

This solution has its limits for us.

- First of all, TEXAID takes back everything, like a "waste disposal center". But what happens to the shoes that are not resold? No recovery is to be expected on this side.

- Secondly, the resale. Part of the profit goes to the main Swiss charities and part to TEXAID. This has never shocked us. Indeed, sorting is expensive and the originality of the system is to be a private partnership / charities. It seems normal to us that this company makes profits. What is more annoying is that we have no control over the sale of used products that can travel incredible distances to end up in landfills.

What a pity not to valorize all this waste...

At the same time, we have started occasional collaborations with the Vestiaire Social CARITAS / CSP in Geneva, to whom we give unsold goods during the sales. These "solidarity sales" had a great impact on us. We visited the Vestiaire Social and realized that we could have a concrete and local impact with this partnership. It was very motivating for the Benjie team and really meaningful. The only concern was that it was limited and not sustainable.

We give new pairs to the Cloakroom during the last Benjie solidarity sale

« We used all these experiences to build a new approach »

- For shoes in good condition: to dispense with intermediaries and make sure that they directly benefit people in need, where we work. In Geneva and later in the rest of Switzerland. So why not continue our collaboration with the Vestiaire Social?

- For shoes that are too damaged: find a solution to recycle them and make a new material. To achieve this, we launched (and succeeded) a second crowdfunding in June 2022.

THE PRINCIPLE OF THE NEW COLLECTION

The principle is simple:

1/ you bring back your used Benjie in a store in Geneva or you send them by parcel (addresshere). Eventually, we want to develop other collection points throughout Switzerland. Please note the following two points:

- Two feet attached to each other if possible.

- Benjie brand only. Why? Our shoes are MACH certified, which guarantees the non-toxicity of the materials they are made of.

2/ We sort out

3/ Those that can still be worn are given to the Vestiaire Social CSP CARITAS

4/ Those that are too damaged will be crushed to make new Benjie soles.

Pair that can be refurbished

Pair for recycling

5/ A question you might ask yourself: why don't we give a voucher in exchange for the shoes you bring back?

- Our idea is to realize a solidarity operation with your help: on our side, the recycled sole costs three times more than a normal Benjie sole. It's up to us to pay for it. On your side, you offer pairs that you will not use anymore to contribute to an initiative in favor of the preservation of resources.

- This is not a commercial operation to entice you to buy a new pair!

Left: after refurbishment / right: before refurbishment

Bottom: after refurbishment / top: before refurbishment

THE CSP AND CARITAS SOCIAL CHECKROOM IN GENEVA

Once donated to the Cloakroom, the shoes are repaired, cleaned and refurbished by the institution for donation. The beneficiaries are holders of a voucher issued by the social services, the CSP or Caritas Geneva.

Since 2021, the Vestiaire social is facing an extraordinary increase in requests. They were 6500 (+20%) to come and get clothes and household linen. Some items, such as warm coats for women and furry shoes for children, are sorely lacking. As for children's shoes, the most missing sizes are 26 to 30 and 35 to 40 (often adult shoes that are not suitable for children). To make up for this lack, the Cloakroom is sometimes obliged to buy shoes... new.

The display area, where the refurbished shoes are offered, just like in a real store

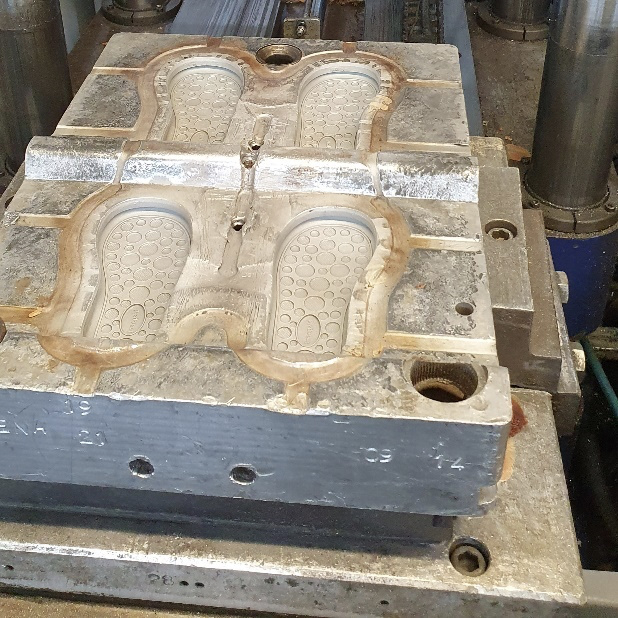

Here is what the aluminum molds look like on a press

THE MANUFACTURING OF THE RECYCLED SOLES IN PORTUGAL

Once a year, we will send back to Portugal the shoes that can no longer be worn. The idea is to take advantage of a delivery of our shoes to leave with a load of used shoes.

The shoes will be sent back to the region of Felgueiras, about 60 kilometers northeast of Porto, near ourfactories. This is a new supplier of soles for us.

By crushing the whole shoe (we just remove the metal), we obtain a powder which, mixed with latex, will be used to manufacture a new sole. To ensure the good flexibility and robustness of the sole, the final material will be a mixture composed of approximately: 40% of this crushed material from the old Benjie, 20% of recycled synthetic rubber and 40% of recycled natural rubber.

Thanks to our crowdfunding in June 2022, we have collected almost 34.000 CHF to make the molds for these new soles. We are now in the process of making the prototypes. But nothing is simple... The soaring price of aluminum (material of the molds), due to the current context, has multiplied by three the price of the molds between the study of the project and its realization.

Step 1 : the drawing on computer Step 2 : the first prototypes

We are now in full development and aim to offer a shoe equipped with a sole made of recycled Benjie for the fall winter 2023 collection!

In order to start manufacturing the soles in June 2023, we need to start collecting used Benjies today! That's why you can bring in your old Benjies now!

In 2021, for our traditional B(L)ACK FRIDAY that promotes less consumption and more recycling, we collected over 300 pairs!

THE LIMITS

This loop is a first step towards circularity. Despite the fact that we recycle 100% of a Benjie (except for the metal), the material generated will only compose 40% of the new sole.

So there is still a long way to go to reach the grail: a new Benjie made entirely from a used Benjie.

However, we are inherently optimistic: we prefer to see this as a positive initiative rather than an imperfect action. Besides, doing "better" is in our mantra...